Addressing Worker Shortages with Automation: A Necessity for the Future

Worker shortages are not a new phenomenon, and they are not confined to any one country. In fact, a recent report by McKinsey highlights that in the world’s eight, largest developed countries—Australia, Canada, France, Germany, Italy, Japan, the United Kingdom, and the United States—the number of job seekers is roughly equal to the number of job vacancies. One of the primary factors contributing to this situation is the ageing population of baby boomers reaching retirement age. This generation has formed a significant part of the manufacturing workforce for many years. As they retire, more job roles are left open with fewer people to fill them, as many young people are not considering manufacturing as a desirable career option.

Internally, worker shortages can cause numerous issues for businesses. With fewer people on the job, current workforces are becoming stretched, and a stretched workforce can quickly become an unhappy one. Employees may feel compelled to work longer hours to meet demands, leading to disengagement in the long run.

This scenario is particularly challenging for those working within the manufacturing sector. Worker shortages may mean that companies are unable to fulfil commitments to clients and customers. Employers are then forced into potential bidding wars to compete with other companies to fill vacancies and retain existing employees. These rising costs can have a knock-on effect on the profitability of the business.

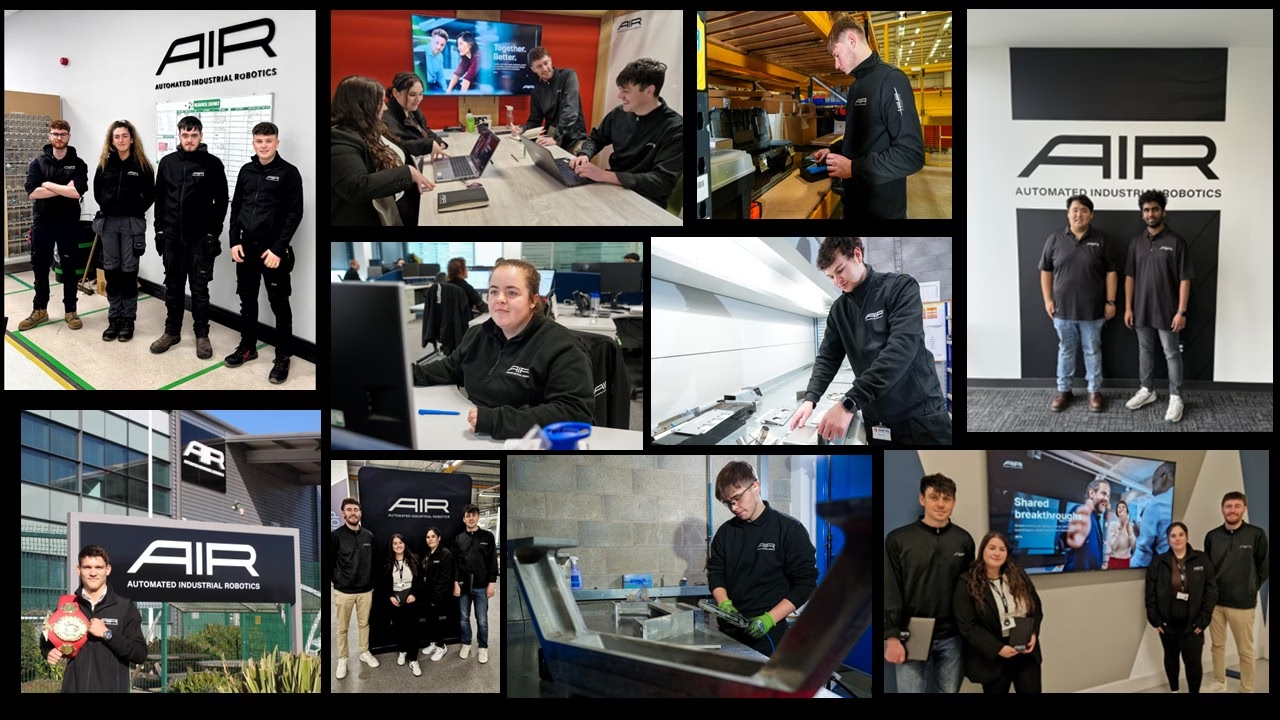

Investing in automation is a game-changer when it comes to addressing worker shortages. At Automated Industrial Robotics -AIR, we believe that automation is now a necessity rather than just an investment opportunity. Over the past twelve months, we have seen inquiries for automation rise by over 50%, with orders coming from various sectors across the globe.

Automation reduces the reliance on human workers without replacing jobs. Instead, it offers the opportunity to upskill workers, equipping them with new skills in automation and technology. It allows workers to spend less time on repetitive manual tasks and more time on value-adding tasks that contribute to their personal development and business objectives.

Moreover, automation can provide a higher level of service for certain processes. Products can be picked and packed uniformly, minimizing mistakes and variances that are common with manual tasks. Production is often disrupted when workers are off sick, feeling tired, or overworked, or simply on annual leave. Automation, on the other hand, doesn’t have downtime unless something needs repairing, offering more predictability and a stable, consistent approach.

Automation can also reduce the time it takes to perform tasks and the need for employees to carry out the same operation repeatedly. It allows businesses to readily identify inefficiency points and delays, which can be corrected immediately. Additionally, it provides an opportunity to introduce precise, complex processes into their operations whilst delivering a return on investment.

Is your company feeling the effects of the worker shortage and considering how automation could help? At AIR, we are global leaders in automation and our specialist business units have helped hundreds of businesses around the world transform their workforce and output through automation. Please contact us at https://industrialrobotics.com/